What are the main benefits of choosing Cool Composers Custom Air Handling Units (AHU) versus Standard Thermal?

Offering a solution to meet unique customer specifications rather than a standard product portfolio which does not lend to customization in the following typical customer design levers:

Control Flexibility – Cool Composers with or without Teamwork™ or customer preferred controls system can be mounted on any Cool Composers Custom AHU solution.

Air Flow – Cool Composers Custom AHU is the solution specifically for outdoor airflow requirements and most cooling technologies including DX, Evap tech (Direct & Indirect), CW, and Economization to meet the site air flow capacity requirements, 2K CFM < Air Flow < 150K CFM.

Component Flexibility – sourcing selection and availability to optimize design to specification requirements, including internal manufacturing capability. Pre-existing envelope size requirements – designed to fit a particular interface or size restriction.

Power – electrical system designs our solution to meet site requirements

What are typical design inputs needed for a Cool Composers Custom Air Handling Units (AHU)?

For a successful custom specification Basis of Design, sales relationship is the key to understanding the bespoke customer requirements. The sales team works with application engineering throughout the initial project information stage to optimize internal drivers, (quality, delivery, cost) with program specifications. Typical initial basic design inputs for Cool Composers Custom AHU would be: defined thermal technology, ambient & design, equipment and data center footprint, geographic location and conditions, airflow, thermal load.

Is Cool Composers Custom Air Handling Units (AHU) more expensive?

In many cases a Custom solution lowers the total installed costs to the end customer based on design features that are typically installed on site that have been included in the unit construction. A custom solution will be offered with attributes to meet a customer specification that will also have a target price unique to that program. The Custom AHU $/cfm’s may be higher than a Standard AHU $/cfm pricing structure due to the expanded attribute value of the Cool Composers Custom AHU solution.

Is Cool Composers Custom Air Handling Units (AHU) longer delivery?

The total project engagement is a function of the customer input required to design a custom solution. Our design engineers work hand in hand with the customer design team to deliver a bespoke solution based on unique climate, physical, thermal and control parameters. Once designed, standard components are included in the BOM as much as requirements allow; however, our component flexibility and sourcing options are utilized to optimize the delivery times.

Does Cool Composers Custom Air Handling Units (AHU) have more cooling options?

Cool Composers Custom AHU allows the specifications to dictate the cooling technology, if the solution will meet customer quality, delivery, and cost targets within the LOB business parameters, including Direct Exchange (DX), Evaporative technology (Direct & Indirect), Chilled Water (CW), and Economization to meet the site requirements in air flows 2K CFM < Air Flow < 150K CFM.

Does Cool Composers Custom Air Handling Units (AHU) carry standard/certifications?

Basic AHU certifications include, but Cool Composers Custom AHU can also review customer specific requirements.

Control flow rate of Air

To avoid fluctuations in the ventilation air volume due to filter contamination, the fan capacity should be step less regulated by controlling its speed. This function is also necessary to adjust airflow supplied to the building to the current demand (e.g. depending on the number of people currently in the building or office). In addition, the step less fan speed control facilitates adjustment of the airflow rate during commissioning of the system.

How is AHU air flow measured?

An anemometer, a test instrument that measures air velocity is used to determine the average airspeed in the duct. Then the average feet per minute is multiplied by the area of the duct in square feet to determine the airflow moving through the duct.

Get kind of answer

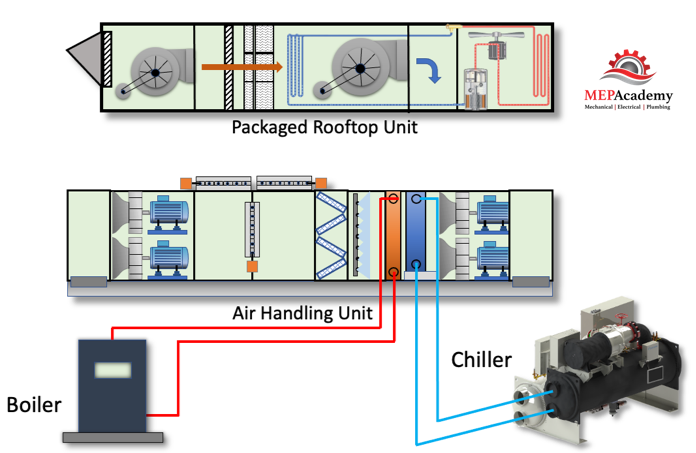

What is AHU ventilation?

An Air Handling Unit (AHU) is used to re-condition and circulate air as part of a heating, ventilating and air-conditioning system. AHUs connect to ductwork that distributes the conditioned air through the building and returns it to the AHU.

How do you check for duct leaks?

Turn your HVAC system on and return to the areas where ductwork is accessible. Check the connections between each section of duct, placing your hand over the metal. If you feel air against your hand, the connection is loose and there is an air leak. A common place for leaks is the duct joints.

What is AHU & FCU?

AHU and FCU are both included in the HVAC system. AHUs are usually connected to a central HVAC system whereas an FCU can function or be installed itself. Because of this, it is often the AHU that is used to ventilate an entire building whereas FCUs are used in smaller and often local spaces only. .

Copyright & Design By Hi5 E Solution - 2023