Filters

The filter section is designed for easy removal of filters. The Filter Frames are made out of heavy guage Galvanised sheet sheet. The Pre filters are made of non woven filter fabric in multiple pleated form to provide more filtration area fitted within extruded Aluminium frame with bonding agent. The filters are capable of filtering dust particles up to 10µ having 90% to 99.99% efficiency, 5µm, 3µm, 1µm and 0.3µm. The initial efficiency of these filters with atmospheric dust is greater than 98%.

By pass damper

along with quadrant and manual locking can be provided as optional feature.

Cooling coil

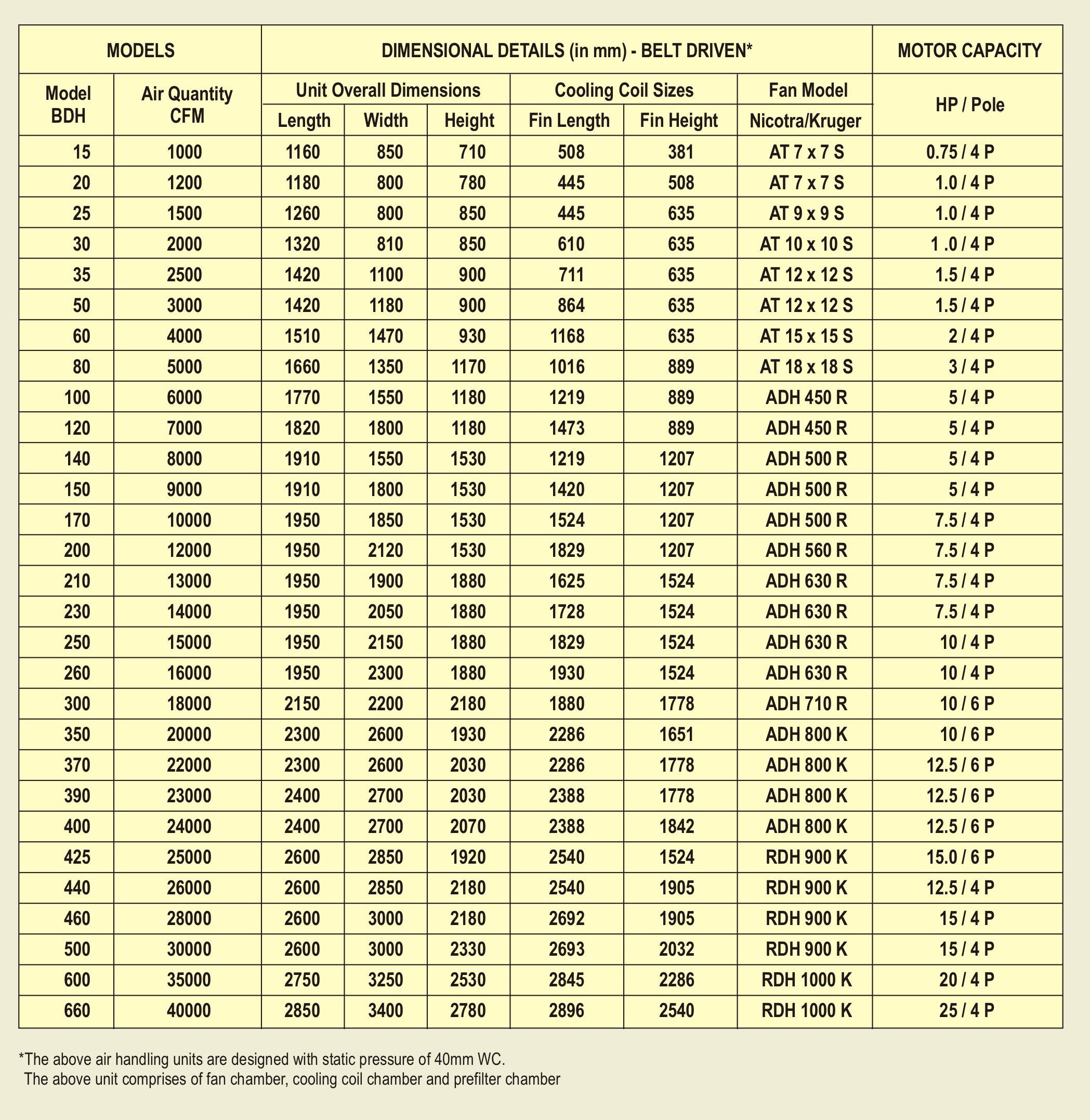

The cooling coil is manufactured to achieve maximum cooling performance by using Aluminium fins with Zigma corrugation and mild ripples / Hydrophilic Blue Fins designed for minimum air pressure drop. Cooling coils have 12 fins per inch. The copper tubes brazed with hair pin bends to reduce the usage of U bends. The end support plates of the cooling coils are made with Galvanised sheets / Stainless Steel Sheet of adequate thickness based on site requirement. Each cooling coil copper tubes (Plain / IGT) are expanded to obtain proper bonding with the fins by hydro pneumatically / bullet expansion. The cooling coil headers are made from MS / Cu pipe. Cooling coils are normally with 4 Rows for comfort application. Based on design conditions cooling coils can be provided 6 / 8 Row as optional.

Pre Heat / Reheat Coils with Hot Water/ Steam can be provided as optional item.

The maximum horizontal length of the finned coil is determined by the working width of the interior of the air handling unit and expressed in mm. The depth of the heating/cooling unit is composed of a specific number of rows of tubes facing the direction of air flow. The number of rows is calculated according to the air flow conditions at the inlet and outlet of the unit, based on the cooling or heating energy used by the equipment

Condensate Drain Pan

Condensate Pan is fabricated with Stainless steel Sheet with gradient towards the drain outlet to avoid water stagnation in the tray. The insulation is carried out with high efficient closed cell elastomeric foam / Polyurathene Foam. Suitable Heavy Steel / Stainless Steel bridges are provided to support the cooling coil. The drain pan is easily accessible for periodic cleaning.

Drift Arrestor

When the velocity across the coil is 2.5m/s more or when the water content of the air is greater than 10.5 g/kg of dry air, a specially designed GI / PVC Drift Arrestor is placed to arrest carryover of mist particles and allow clean and cool air to pass through.

"We Care for smaller details and we make our efforts worthier"

Kalyana Raman S- Head Of Chennai Commposers